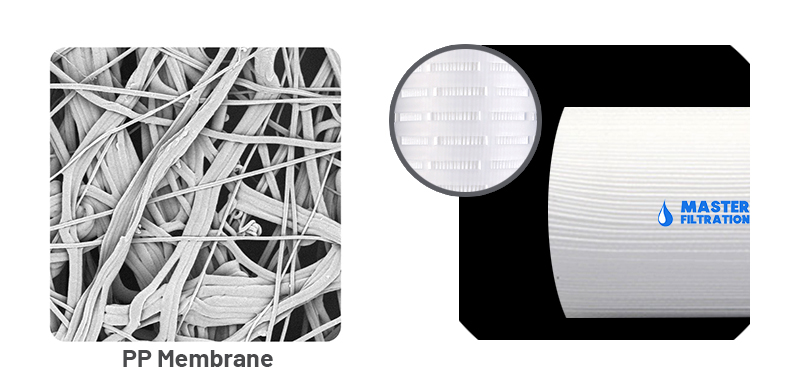

MFPA Series PP Membrane Absolute Pleated Filter Cartridge, composed of double gradient high performance nano-level high precision polypropylene microfiber membrane and inforced PP frame shell. The nano microfiber membrane ensures absolute filtration efficiency and guarantee filter cartridge safety.

- Double gradient high precision fine fiber layer

- High contaminant capacity and high filter efficiency

- 100% new PP material, good chemical compatibility

- Hot melt welding technology, no adhensive, no glue, no leakage

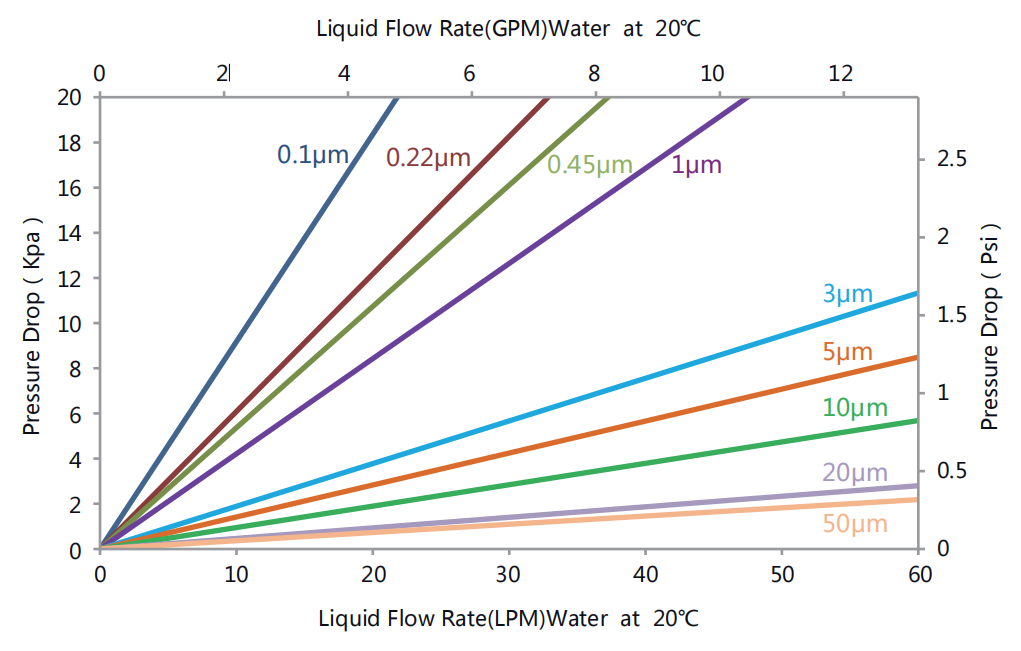

- Deep filtration, large filtration area, low pressure drop

- Strong contamination capacity, long service life

|

Cartridge Dimensions |

Length(DOE end caps) |

10"- 254mm, 20"- 508mm, 3C"-762 mm, 40"- 1016mm |

|

Outer Diameter |

69mm |

|

|

Inner Diameter |

28mm, 30mm |

|

|

Filtration Area(m2) |

0.65 m2 per 10" |

|

|

Materials |

Filter Media: |

Polypropylene |

|

Support Layers: |

Polypropylene |

|

|

Micron Rating: |

0.1, 0.2, 0.45, 0.65, 1.0, 3.0, 5.0um (customized) |

|

|

Inner core: |

Polypropylene |

|

|

Outer Cage, End caps: |

Polypropylene |

|

|

Seal Method: |

Thermal Bonded, No Adhesives |

|

|

O-rings/gaskets: |

Silicone, Nitrile, EPDM. Viton, Teflon, etc |

|

|

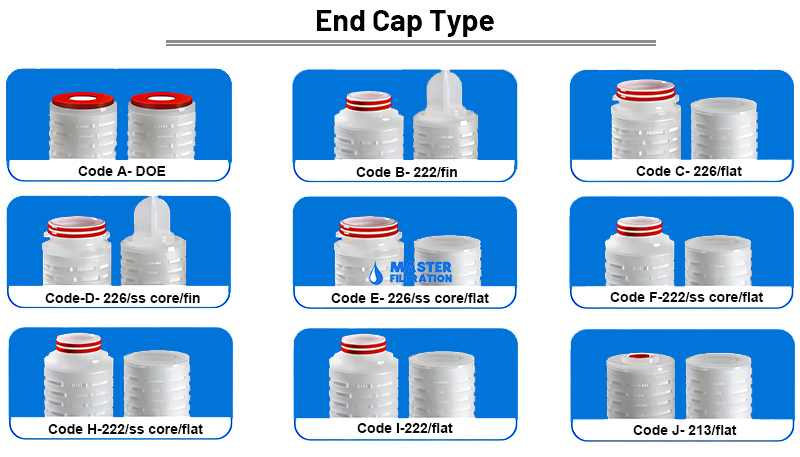

End cap: |

DOE, 222,226,215 and others |

|

|

Operating conditions |

Normal Operating Temperature: |

Upto 60℃ (140°F) |

|

Max.Operating Temperature.: |

80℃ (172°F) at △P≤1.0 bar (14psi) |

|

|

Max. Differential Pressure |

|

|

|

Normal Flow direction: |

4.2 bar (60 psi) at 25℃ (77°F) |

|

|

Reverse flow direction: |

2.1 bar (30 psi) at 25℃ (77°F). |

|

|

PH Value compatibility: |

1-13 PH |

|

|

Sterilization: |

Steam Sterilization for 30 minutes at 121±2 ℃, Cumulative Time:15 hours; |

|

|

|

Flush with hot water at 82℃(180°F) for 30 minutes, at △P≤1.0 bar (14psi) - Recommended. |

|

|

Cartridge Safety |

Endotoxin: |

<0.25 EU/ml |

|

Exlractables: |

0.03g/10" |

|

|

Remark |

We are factory and support customized specification |

|

|

Integrity Test (Imported Membrane) |

||||

|

Aperture(um): |

0.10 |

0.20 |

0.45 |

1.00 |

|

Minimum bubble point(Mpa): |

≥0.015 |

≥0.011 |

≥0.009 |

≥0.003 |

|

* Test Liquid: 95% isopropyl alcohol or ethyl alcohol at 25℃ |

||||

|

Integrity Test (Imported Hydrophilic Membrane) |

|||

|

Aperture(um): |

0.10 |

0.20 |

0.45 |

|

Minimum bubble point(Mpa): |

≥0.016 |

≥0.012 |

≥0.009 |

|

* Test Liquid: 95% isopropyl alcohol or ethyl alcohol at 25℃ |

|||

|

Model |

Length |

Removal Rating |

End Cap Type |

Seal Material |

Core |

|

MFPA |

5 = 5” |

0.1 = 0.1μm |

A = DOE |

S = Silicone |

P = PP core |

|

10 = 10” |

0.22 = 0.22μm |

B = 226/fin |

E = EPDM |

S = SS core |

|

|

20 = 20” |

0.45 = 0.45μm |

C = 226/Flat |

B = NBR |

|

|

|

30 = 30” |

1 = 1μm |

D = 226/Fin/SS |

V = Viton® |

|

|

|

40 = 40” |

3 = 3μm |

E = 226/Flat/SS |

T = Teflon® |

|

|

|

50 = 50” |

5 = 5μm |

F = 222/Flat/SS |

|

|

|

|

|

10 = 10μm |

G = 222/Fin/SS |

|

|

|

|

|

20 = 20μm |

H = 222/Flat |

|

|

|

|

|

50 = 50μm |

I = 222/Fin |

|

|

|

|

|

|

J = 213/Flat |

|

|

|

Water Treatment |

|

Process Water, RO Pre-filtration, Condensate Water, Potable Water System, Wastewater Treatment, Sea Water Desalination, Ballast Water Treatment. |

|

Industrial |

|

LEDS, Wastewater, Pulp & Paper, Tank Venting, Fine Chemicals, Surface Finishing. |

|

Power Plant |

|

CVCS, RWCU, Spent Fuel Pool, Suppression Pool, Condensate Polishing, Steam Generator Blow Down, Stator Cooling Water Treatment, Liquid Radioactive Water Treatment. |

|

Petrochemical |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Food & Beverage |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Oil & Chemicals |

|

Painting, In kjet Printers, Solvent Filtration, Chemical Filtration, Oil & Gas Filtration, Ink jet Inks Filtration, Automotive Painting & Paint. |

|

Microelectronics |

|

LCD Cleaning, CMP Filtration, Flat Panel Film, Semiconductor Wastewater, Electronic Chemical Filtration, Typical Ultrapure Water System, Wafer Grinding/Cutting Wastewater. |

|

Pharmaceuticals |

|

Opthalmic Filtration, Pharmaceutical Water, Blood Plasma Product, Formulation LVP/SVP Filtration, Sterile Filtration & Bioburden Control, API's, Intermediates, Fermentation Broths, Precious Metal Catalyst Removal/Recovery. |