Master Filtration MFBC Series Microfiber Non Woven PP PE liquid Filter Bag, uses micro fiber as filter media, and adapts welding technology to avoid fine particles flowing out through sewing hole, designed for high precision filtration. The filter material of microfiber filter bag is 100% polypropylene, which has lipophilicity and hydrophobic characteristics. Gradient filter structure design to block large particles at surface, and trap fine particles inside. The pp microfiber high efficiency filter bag is widely applied in semi-conductor, fine chemical industry, food and medicine, paint ink, water treatment and other liquid filtration fields. Excellent lipophilicity characteristics makes it especially suitable for paint and ink industry oil removal.The best replacement pressure difference is 0.10Mpa and the maximum is 0.16Mpa.

- High speed cooling no silicone oil sewing machine, without silicone oil pollution

- Gradient filter structure, increase contaminant capacity

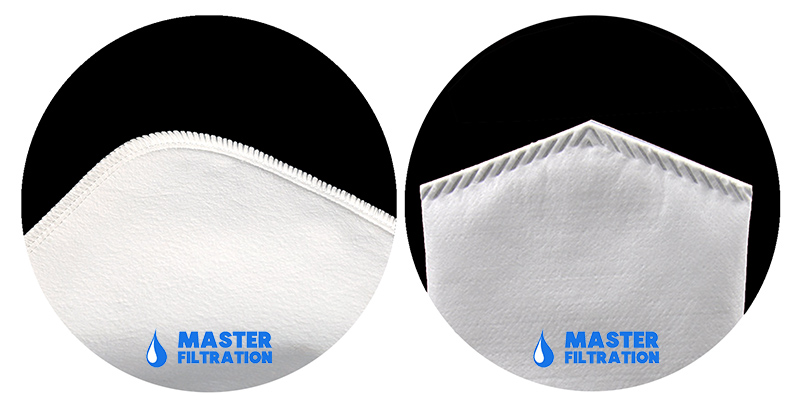

- Surface singeing and calendering treatment, prevent fiber dropping

- Pure welding technology, avoid fine particle bypass leakage

- 3D deep filtration structure, high contaminant capacity

- Good chemical corrosion resistance,able to be used in acid, alkali and other corrosive liquids

- High porosity, small fiber pore structure, good air permeability, high flow rate

- Simple operation, easy installation and replacement

- Wide filtration accuracy setectable:0.2~200um

|

Model: |

MFBC-1 |

MFBC-2 |

MFBC-3 |

MFBC-4 |

MFBC-5 |

|

Size: |

180*450mm |

180*810mm |

105*230mm |

105*380mm |

150*560mm |

|

Flow rate (M3/H): |

20 |

40 |

6 |

12 |

20 |

|

Filtration area |

0.25 ㎡ |

0.5 ㎡ |

0.09 ㎡ |

0.16 ㎡ |

0.25 ㎡ |

|

Filtration volume: |

8 L |

17 L |

1.3 L |

2.5 L |

8L |

|

Filtration media: |

Polyester(PE), PP |

||||

|

Ring material: |

Galvanized ring, SS304, PP or PE plastic ring |

||||

|

Filtration class: |

0.2,0.5,1,5,10,25,50,80,100,125,150,200micron (um) |

||||

|

Bag construction: |

Sewing/welding |

||||

|

Working temperature: |

PP<90℃;PE<130℃; |

||||

|

Application: |

Used for water, beverage, industry water, chemical liquid, oil, paint, seawater desalination, food, pharmaceuticals, biotech,dairy, brewing, semiconductor, RO filtration system. |

||||

|

Remark |

We are factory and support customized specification |

||||

|

MICRON, MESH CONVERSION CHART |

||||||

|

Micron |

1 |

2 |

5 |

10 |

15 |

20 |

|

Mesh |

12500 |

6250 |

2500 |

1250 |

800 |

625 |

|

|

|

|

|

|

|

|

|

Micron |

25 |

33 |

35 |

50 |

53 |

63 |

|

Mesh |

500 |

425 |

400 |

300 |

270 |

230 |

|

|

|

|

|

|

|

|

|

Micron |

80 |

88 |

100 |

125 |

150 |

200 |

|

Mesh |

200 |

170 |

150 |

120 |

100 |

80 |

|

|

|

|

|

|

|

|

|

Micron |

210 |

250 |

354 |

420 |

500 |

595 |

|

Mesh |

70 |

60 |

45 |

40 |

35 |

30 |

|

Water Treatment |

|

Process Water, RO Pre-filtration, Condensate Water, Potable Water System, Wastewater Treatment, Sea Water Desalination, Ballast Water Treatment. |

|

Industrial |

|

LEDS, Wastewater, Pulp & Paper, Tank Venting, Fine Chemicals, Surface Finishing. |

|

Power Plant |

|

CVCS, RWCU, Spent Fuel Pool, Suppression Pool, Condensate Polishing, Steam Generator Blow Down, Stator Cooling Water Treatment, Liquid Radioactive Water Treatment. |

|

Petrochemical |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Food & Beverage |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Oil & Chemicals |

|

Painting, In kjet Printers, Solvent Filtration, Chemical Filtration, Oil & Gas Filtration, Ink jet Inks Filtration, Automotive Painting & Paint. |

|

Microelectronics |

|

LCD Cleaning, CMP Filtration, Flat Panel Film, Semiconductor Wastewater, Electronic Chemical Filtration, Typical Ultrapure Water System, Wafer Grinding/Cutting Wastewater. |

|

Pharmaceuticals |

|

Opthalmic Filtration, Pharmaceutical Water, Blood Plasma Product, Formulation LVP/SVP Filtration, Sterile Filtration & Bioburden Control, API's, Intermediates, Fermentation Broths, Precious Metal Catalyst Removal/Recovery. |