Master Filtration MFHK Series 1 & 2 O Ring High Flow Pleated Filter Cartridge Replaces Parker Magaflow, using pleated polypropylene membrane filter material, up to 1300L/min filtration capacity, effectively reducing filter cartridge quantity. Adopting deep fine membrane filtermedia, multilayer gradient pore filter structure design, achieves higher contaminant dust capacity, longer service life time.

- 100% new PP material, excellent chemical ability

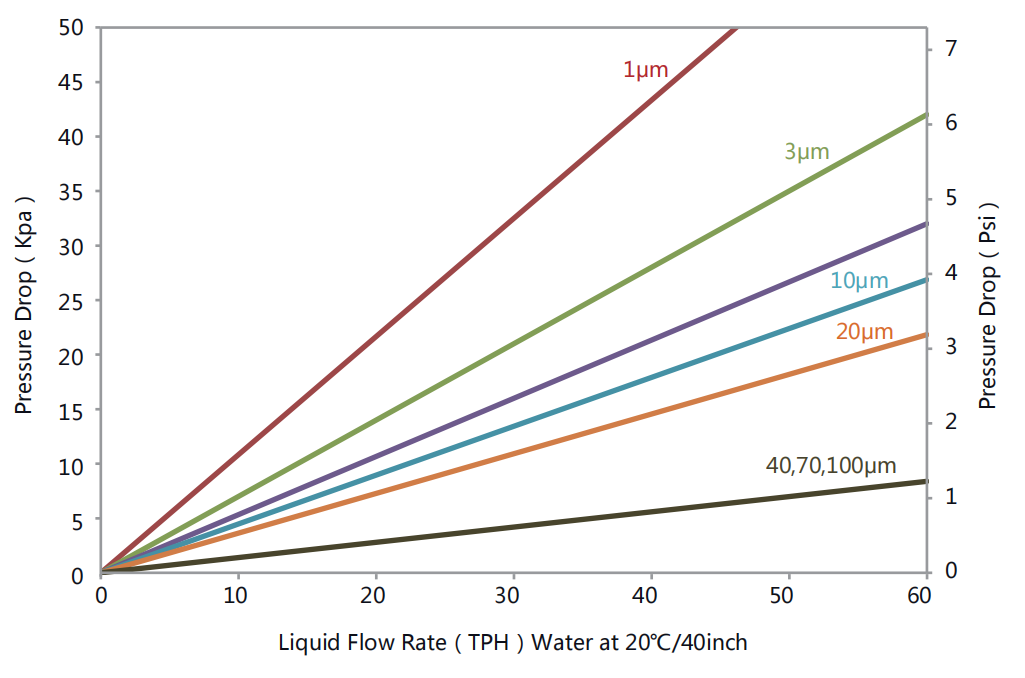

- Large filtration area, high flow ability, low pressure drop

- Good contaminant and dust capacity

- Ultrasonic hot melting, no chemical glue

- PP inside support enforced frame

- Handle design, quick installation

- Multiple precision and length selectable

- Same size as Parker MHF

|

Cartridge Dimensions |

Length |

40"-1016mm; 60"- 1524mm; |

|

Outer Diameter |

6.0 inches (152mm) |

|

|

Micron Rating: |

1 5 10 15 20 40 70 100 um (customized) |

|

|

Materials |

Filter Media: |

Polypropylene pp, fiber glass |

|

Support Layers: |

Polypropylene pp |

|

|

Inner core: |

Polypropylene |

|

|

Outer Cage, End caps: |

Polypropylene |

|

|

Seal Method: |

Thermal Bonded, No Adhesives |

|

|

O-rings/gaskets: |

Silicone, Nitrile, EPDM, Viton, Teflon, etc |

|

|

Operating conditions |

Normal Operating Temperature: |

≤ 60℃(140°F) |

|

Max.Operating Temperature.: |

82℃ (PP) ; 121℃ (Fiber glass) |

|

|

Max. Differential Pressure |

3.44bar@82℃ (PP); 3.44bar@121℃(Fiber glass) |

|

|

Recommended replacement pressure : |

2.4Bar @ 20℃ |

|

|

Remark |

We are factory and support customized specification |

|

|

Model |

Length |

Removal Rating |

End Cap Type |

Seal Material |

Core |

|

MFHK |

40=40" |

1=1μm |

A=Single O ring |

S=Silicone |

P=PP |

|

60=60" |

3=3μm |

E = EPDM |

|

||

|

|

5=5μm |

B=Double O-ring |

V = Viton |

|

|

|

|

10= 10μm |

F= E-FKM |

|

||

|

|

20= 20μm |

|

|

|

|

|

|

40= 40μm |

|

|

|

|

|

|

70= 70μm |

|

|

|

|

|

|

100= 100μm |

|

|

|

|

Water Treatment |

|

Process Water, RO Pre-filtration, Condensate Water, Potable Water System, Wastewater Treatment, Sea Water Desalination, Ballast Water Treatment. |

|

Industry |

|

LEDS, Wastewater, Pulp & Paper, Tank Venting, Fine Chemicals, Surface Finishing. |

|

Power Plant |

|

CVCS, RWCU, Spent Fuel Pool, Suppression Pool, Condensate Polishing, Steam Generator Blow Down, Stator Cooling Water Treatment, Liquid Radioactive Water Treatment. |

|

Petrochemical |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Food & Beverage |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Oil & Chemicals |

|

Painting, Inkjet Printers, Sovlent Filtration, Chemical Filtration, Oil & Gas Filtration, Inkjet Inks Filtration, Automotive Painting & Paint. |

|

Microelectronics |

|

LCD Cleaning, CMP Filtration, Flat Panel Film, Semiconductor Wastewater, Electronic Chemical Filtration, Typical Ultrapure Water System, Wafer Grinding/Cutting Wastewater. |

|

Pharmaceuticals |

|

Opthalmic Filtration, Pharmaceutical Water, Blood Plasma Product, Formulation LVP/SVP Filtration, Sterile Filtration & Bioburden Control, API's, Intermediates, Fermentation Broths, Precious Metal Catalyst Removal/Recovery. |