Master Filtration MFHP Series High Flow Pleated Filter Cartridge Replaces Pall, adopting PP deep fine fiber membrane as the main filter layer, 6" (152mm) large diameter, unidirectional opening end, gradient pore. Specially designed from inside tooutside liquid flow to ensure that all particles are blocked in filter cartridge. The high flow design reduces filter element quantity and replacements installation time, greatly saving the equipment investment. Various precision selectable to adapt to different application requirements.

- Good contaminant and dust capacity

- Ultrasonic hot melting, no chemical glue

- Large filtration area, high flow ability

- PP inside and outside support inforced frame

- Handle design, quick installation

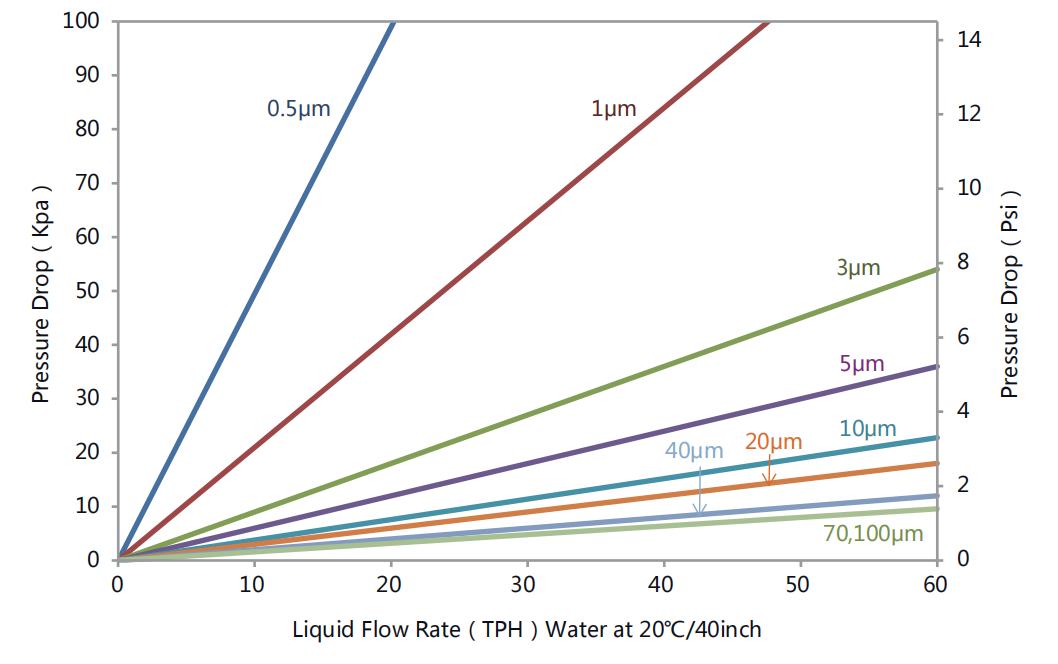

- Multiple 0.5μm to 100μ m precision and 40'' to 60'' length selectable

|

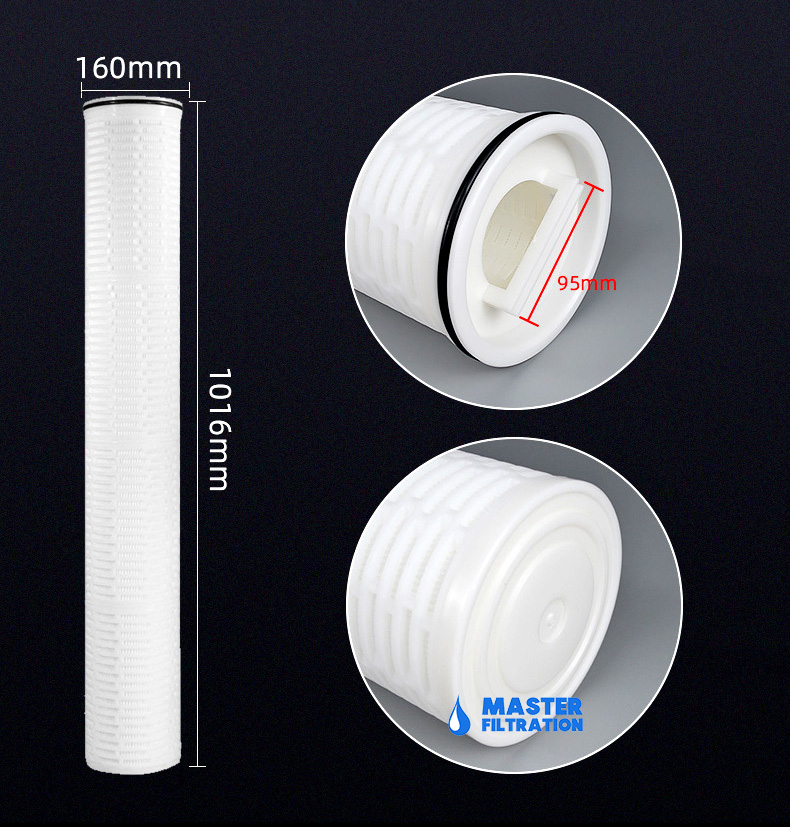

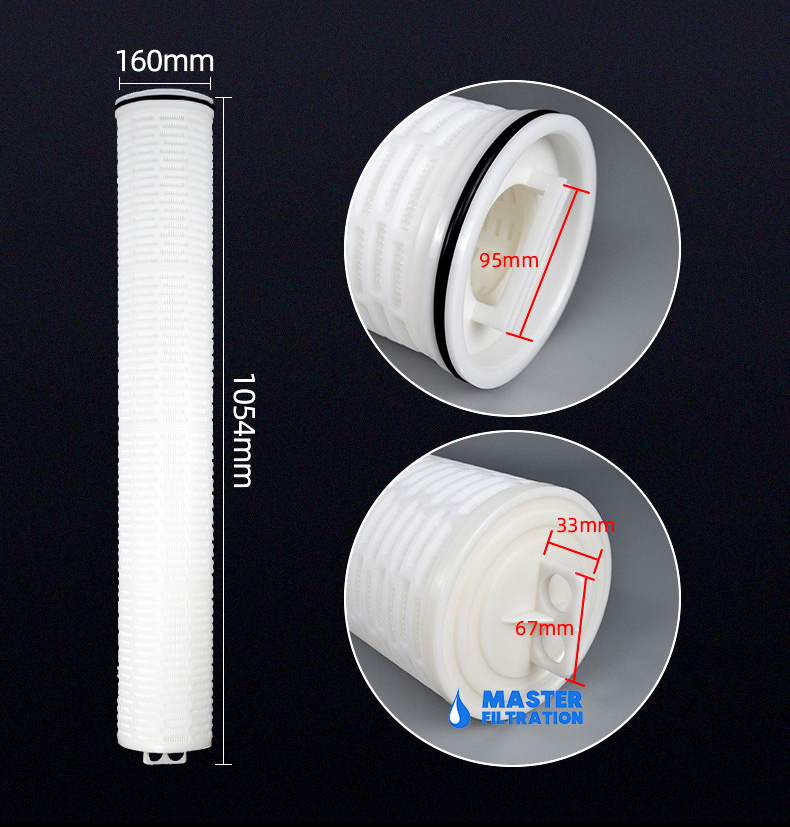

Cartridge Dimensions |

Length |

40"-1016mm; 60"- 1524mm; |

|

Outer Diameter |

6.0 inches (152mm) |

|

|

Micron Rating: |

1 5 10 15 20 40 70 100 um (customized) |

|

|

Materials |

Filter Media: |

Polypropylene pp, fiber glass |

|

Support Layers: |

Polypropylene pp |

|

|

Inner core: |

Polypropylene |

|

|

Outer Cage, End caps: |

Polypropylene |

|

|

Seal Method: |

Thermal Bonded, No Adhesives |

|

|

O-rings/gaskets: |

Silicone, Nitrile, EPDM, Viton, Teflon, etc |

|

|

Operating conditions |

Normal Operating Temperature: |

≤ 60℃(140°F) |

|

Max.Operating Temperature.: |

82℃ (PP) ; 121℃ (Fiber glass) |

|

|

Max. Differential Pressure |

3.44bar@82℃ (PP); 3.44bar@121℃(Fiber glass) |

|

|

Recommended replacement pressure : |

2.4Bar @ 20℃ |

|

|

Remark |

We are factory and support customized specifications |

|

|

Model |

Length |

Removal Rating |

Seal material |

Core |

|

MFHP |

40=40" |

0.5= 0.5μm |

S=Silicone |

P=PP |

|

60=60" |

1=1μm |

E=EPDM |

|

|

|

|

3=3μm |

N=NBR |

|

|

|

|

5=5μm |

V=Viton |

|

|

|

|

10= 10μm |

C=Buna |

|

|

|

|

20= 20μm |

|

|

|

|

|

40= 40μm |

|

|

|

|

|

70= 70μm |

|

|

|

|

|

100= 100μm |

|

|

|

Water Treatment |

|

Process Water, RO Pre-filtration, Condensate Water, Potable Water System, Wastewater Treatment, Sea Water Desalination, Ballast Water Treatment. |

|

Industry |

|

LEDS, Wastewater, Pulp & Paper, Tank Venting, Fine Chemicals, Surface Finishing. |

|

Power Plant |

|

CVCS, RWCU, Spent Fuel Pool, Suppression Pool, Condensate Polishing, Steam Generator Blow Down, Stator Cooling Water Treatment, Liquid Radioactive Water Treatment. |

|

Petrochemical |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Food & Beverage |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Oil & Chemicals |

|

Painting, Inkjet Printers, Sovlent Filtration, Chemical Filtration, Oil & Gas Filtration, Inkjet Inks Filtration, Automotive Painting & Paint. |

|

Microelectronics |

|

LCD Cleaning, CMP Filtration, Flat Panel Film, Semiconductor Wastewater, Electronic Chemical Filtration, Typical Ultrapure Water System, Wafer Grinding/Cutting Wastewater. |

|

Pharmaceuticals |

|

Opthalmic Filtration, Pharmaceutical Water, Blood Plasma Product, Formulation LVP/SVP Filtration, Sterile Filtration & Bioburden Control, API's, Intermediates, Fermentation Broths, Precious Metal Catalyst Removal/Recovery. |