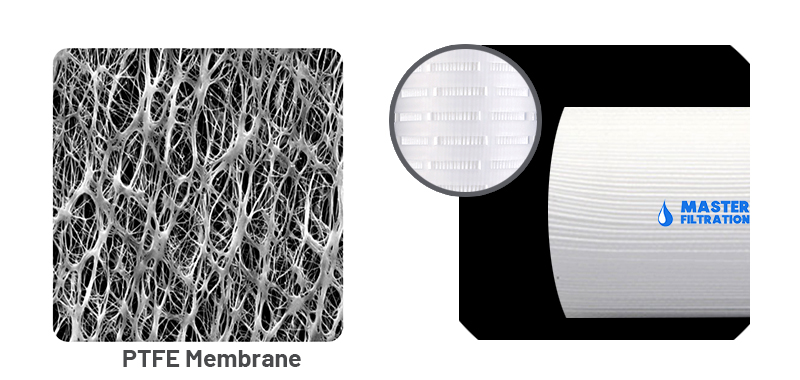

Master Filtration MFPFL Series Hydrophilic PTFE Membrane Pleated Filter Cartridge, is composed of hydrophilic PTFE membrane (surface absolute filtration) and fluid diversion layer. Because of hydrophilic filter material, there is no need of pre-wetting treatment to filter, greatly saving lost of time.Filtration accuracy range 0.1-50 μm. With excellent chemical compatibility, oxidation resistance, and high temperature resistance, it is widely used for gas and liquid sterilization and filtration in microelectronics, pharmacy, chemical and other industries.

- Monolayer hydrophilic PTFE microporous membrane, strong natural hydrophilic

- Perfect sterilization filter materials, ensuring absolute sterilization under wet or dry conditions

- Excellent chemical corrosion, oxidation resistance

- High temperature resistance,low pressure drop

- Hydrodynamic design, high efficiency

|

Cartridge Dimensions |

Length (DOE end caps) |

10"- 254mm, 20"- 508mm, 3C"-762 mm, 40"- 1016mm |

|

Outer Diameter |

69mm |

|

|

Inner Diameter |

28mm, 30mm |

|

|

Filtration Area(m2) |

0.65 m2 per 10" |

|

|

Materials |

Filter Media: |

Hydrophilic PTFE membrane |

|

Support Layers: |

Polypropylene |

|

|

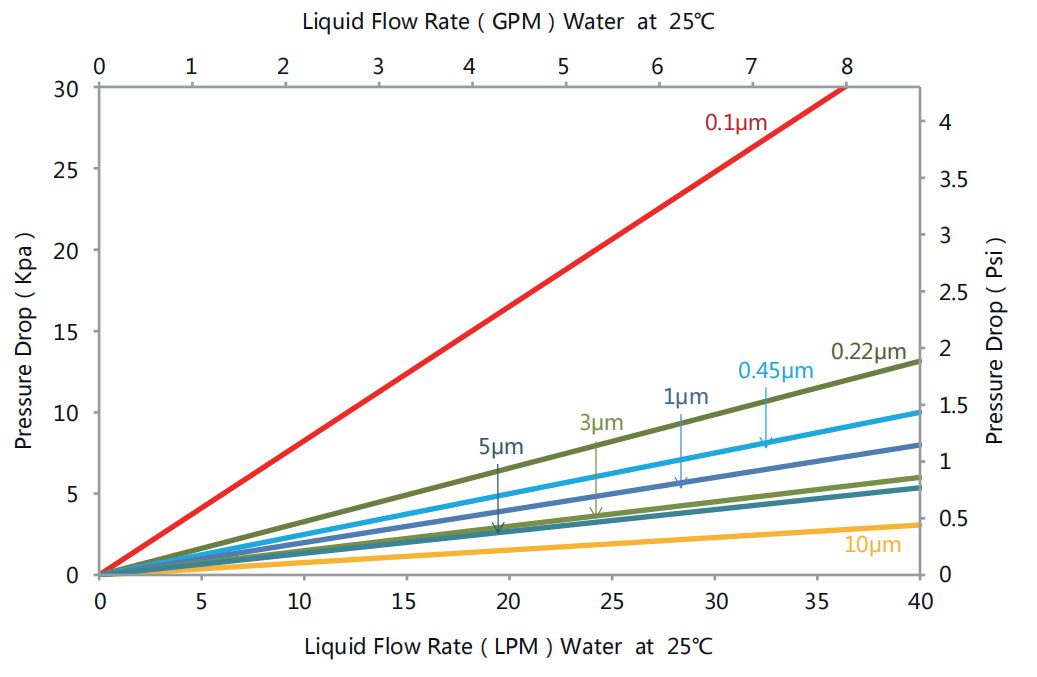

Micron Rating: |

0.1, 0.2, 0.45, 0.65,1.0, 3.0,5.0 um (customized) |

|

|

Inner core: |

Reinforced Polypropylene |

|

|

Outer Cage, End caps: |

Reinforced Polypropylene |

|

|

Seal Method: |

Thermal Bonded. No Adhesives |

|

|

O-rings/gaskets: |

Silicone, Nitrile, EPDM, Viton, Teflon, etc |

|

|

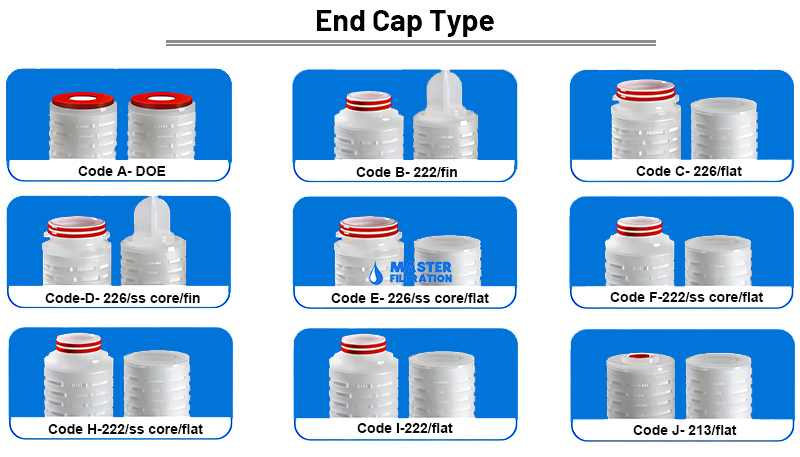

End cap: |

DOE, 222,226,215 and others |

|

|

Operating conditions |

Normal Operating Temperature: |

≤ 65°C(140°F) |

|

Max.Operating Temperature.: |

90°C (194°F) at △≤1.0 bar (14psi) |

|

|

Max. Differential Pressure |

|

|

|

Normal Flow direction: |

4.2 bar (60 psi) at 25°C (77°F) |

|

|

Reverse flow direction: |

2.1 bar (30 psi) at 25°C (77°F). |

|

|

PH Value compatibility: |

1-14PH |

|

|

Sterilization: |

Steam Sterilization for 30 minutes at 121±2 °C, 100 cycles. Autoclave 30minutes (optional) |

|

|

Cartridge Safety |

Endotoxin: |

<0.25 EU/ml |

|

Extractables: |

0.03g/10" |

|

|

Remark |

We are factory and support customized specification |

|

|

Integrity Test ( Hydrophilic PTFE Membrane) |

|||||

|

Membrane |

Aperture(um): |

0.10 |

0.20 |

0.45 |

1.00 |

|

Imported Hydrophilic PTFE Membrane |

Minimum bubble point(Mpa): |

≥0.12 |

≥0.08 |

≥0.04 |

/ |

|

Domestic Hydrophilic PTFE Membrane |

≥0.10 |

≥0.06 |

≥0.035 |

≥0.02 |

|

|

* Test Liquid: 60% isopropyl alcohol at 25℃ |

|||||

|

Model |

Length |

Removal Rating |

End Cap Connection |

Seal Material |

Core |

|

MFPFL |

5=5" |

0.1= 0.1μm |

A = DOE |

S=Silicone |

P=PP |

|

10=10" |

0.22= 0.22μm |

B = 226/FIN |

E = EPDM |

S=Stainless steel |

|

|

20=20" |

0.45= 0.45μm |

C=226/Flat |

N=NBR |

|

|

|

30=30" |

1=1μm |

D=226/Fin/SS |

V = Viton |

|

|

|

40=40" |

5=5μm |

E=226/Flat/SS |

T=Teflon |

|

|

|

|

10=10μm |

F=222/Flat |

F=E-FKM |

|

|

|

|

|

G=222/Fin |

|

|

|

|

|

|

H=222/Fin/SS |

|

|

|

|

|

|

I=222/Flat/SS |

|

|

|

|

|

|

J=213/Flat |

|

|

|

Water Treatment |

|

Process Water, RO Pre-filtration, Condensate Water, Potable Water System, Wastewater Treatment, Sea Water Desalination, Ballast Water Treatment. |

|

Industrial |

|

LEDS, Wastewater, Pulp & Paper, Tank Venting, Fine Chemicals, Surface Finishing. |

|

Power Plant |

|

CVCS, RWCU, Spent Fuel Pool, Suppression Pool, Condensate Polishing, Steam Generator Blow Down, Stator Cooling Water Treatment, Liquid Radioactive Water Treatment. |

|

Petrochemical |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Food & Beverage |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Oil & Chemicals |

|

Painting, In kjet Printers, Solvent Filtration, Chemical Filtration, Oil & Gas Filtration, Ink jet Inks Filtration, Automotive Painting & Paint. |

|

Microelectronics |

|

LCD Cleaning, CMP Filtration, Flat Panel Film, Semiconductor Wastewater, Electronic Chemical Filtration, Typical Ultrapure Water System, Wafer Grinding/Cutting Wastewater. |

|

Pharmaceuticals |

|

Opthalmic Filtration, Pharmaceutical Water, Blood Plasma Product, Formulation LVP/SVP Filtration, Sterile Filtration & Bioburden Control, API's, Intermediates, Fermentation Broths, Precious Metal Catalyst Removal/Recovery. |