Master Filtration MFSB Series Stainless Steel Multi Bag Filter Housing, adopting side to bottom mode, is suitable for high flow and large solid sediment liquid. Filter bag quantity can be increased from 2 bags to 24 bags. SS304, SS316L filter housing with inner & outside surface anti-corrosive coating is suitable for various acid, alkali and hot temperature liquid. Wide top inlet makes liquid evenly be distributed on the top of filter bag, avoiding turbulence bad effect.

- Compact structure and well space utilization

- Simple installation and convenient operation

- Horizontal opening, vertical opening to solve different site limits

- Unique three-point pressing device to ensure filter bag good sealing

- Humanized design, V-hoop lock, only 30 seconds to open

- Wide filtration accuracy: 0.5~1200um

- Large filtration area, low cost

|

Filter housing material: |

SS304, SS316 |

|

Filter bag material: |

PP, Polyester,Nylon,PTFE,SS304,SS316 |

|

Filter bag qty: |

2~24 pcs |

|

Removal rate: |

0.5~1700um |

|

Working temperature: |

0~100℃ |

|

Max differential pressure: |

2.4 bar |

|

Replacement differential pressure: |

1.0 bar |

|

Gasket: |

Silicone, NBR, EPDM, FKM, PTFE |

|

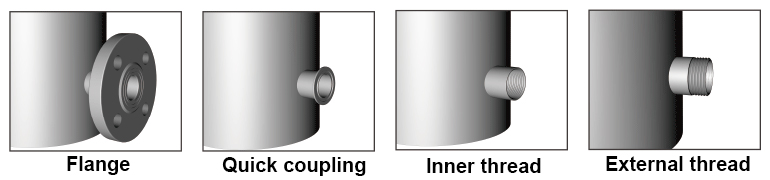

Inlet&outlet: |

Flange,tri-clamp, thread |

|

Surface finishing: |

Satin finish, polishing finish |

|

Model |

Filter bag qty (pcs) |

Diameter (mm) |

Height (mm) |

Inlet/outlet dia |

Flow rate (m3/h) |

Filtration area(㎡) |

|

MFSB-2 |

2#*2 |

400 |

1600 |

DN65 |

60 |

1 |

|

MFSB-3 |

2#*3 |

450 |

1610 |

DN80 |

90 |

1.5 |

|

MFSB-4 |

2#*4 |

500 |

1720 |

DN100 |

120 |

2 |

|

MFSB-5 |

2#*5 |

550 |

1730 |

DN125 |

150 |

2.5 |

|

MFSB-6 |

2#*6 |

600 |

1800 |

DN150 |

180 |

3 |

|

MFSB-7 |

2#*7 |

650 |

1900 |

DN150 |

220 |

3.5 |

|

MFSB-8 |

2#*8 |

750 |

2030 |

DN200 |

240 |

4 |

|

MFSB-10 |

2#*10 |

850 |

2100 |

DN200 |

300 |

5 |

|

MFSB-12 |

2#*12 |

900 |

2180 |

DN200 |

360 |

6 |

|

MFSB-14 |

2#*14 |

950 |

2180 |

DN200 |

420 |

7 |

|

We are factory and support customized specifications. |

||||||

|

Water Treatment |

|

Process Water, RO Pre-filtration, Condensate Water, Potable Water System, Wastewater Treatment, Sea Water Desalination, Ballast Water Treatment. |

|

Industry |

|

LEDS, Wastewater, Pulp & Paper, Tank Venting, Fine Chemicals, Surface Finishing. |

|

Power Plant |

|

CVCS, RWCU, Spent Fuel Pool, Suppression Pool, Condensate Polishing, Steam Generator Blow Down, Stator Cooling Water Treatment, Liquid Radioactive Water Treatment. |

|

Petrochemical |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Food & Beverage |

|

Lube Oil Filtration, Amine Sweetening, Chemicals Filtration, Desiccant Dehydration, Completion Fluid Filtration, Oil & Natural Gas Filtration, Injection Well Water Filtration. |

|

Oil & Chemicals |

|

Painting, Inkjet Printers, Sovlent Filtration, Chemical Filtration, Oil & Gas Filtration, Inkjet Inks Filtration, Automotive Painting & Paint. |

|

Microelectronics |

|

LCD Cleaning, CMP Filtration, Flat Panel Film, Semiconductor Wastewater, Electronic Chemical Filtration, Typical Ultrapure Water System, Wafer Grinding/Cutting Wastewater. |

|

Pharmaceuticals |

|

Opthalmic Filtration, Pharmaceutical Water, Blood Plasma Product, Formulation LVP/SVP Filtration, Sterile Filtration & Bioburden Control, API's, Intermediates, Fermentation Broths, Precious Metal Catalyst Removal/Recovery. |